Fabrication of Orientation-Controlled Orthoferrite Films

Lippmaa and Nakatsuji Groups

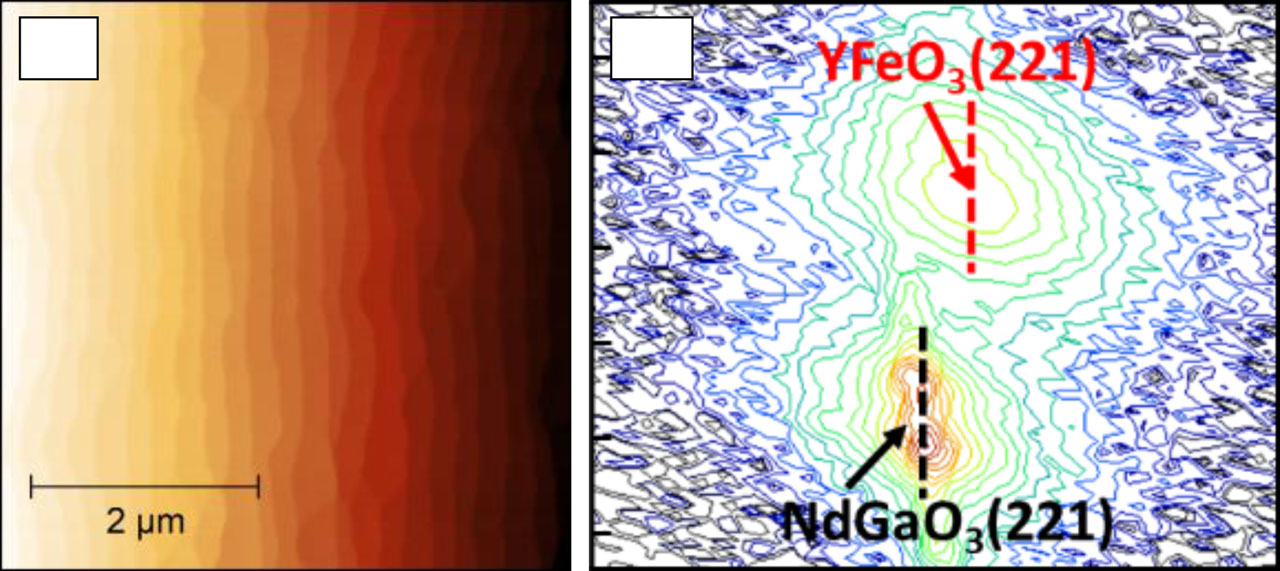

YFeO3 is an orthorhombic antiferromagnet with a distorted pseudocubic perovskite structure. The spins are slightly canted, giving the material a small spontaneous residual magnetic moment. Single crystals of YFeO3 have been shown to have a magnon decay length of several hundred nm. As the spin ordering temperature is about 640 K and YFeO3 has no spin-flop transitions below the ordering temperature, it can be a useful material for designing room-temperature antiferromagnetic spintronic devices. The choice of suitable antiferromagnets is small, with most experimental work focusing on hematite α-Fe2O3. However, device design generally requires thin films and it is known for α-Fe2O3 that the magnon decay length in a thin film is much shorter than in a single crystal. In Fe2O3, this reduction of the decay length may be related to the small grain size and high defect density, which is an intrinsic problem with iron oxides due to the existence of multiple crystalline phases with the same nominal film composition. Compared to hematite, the orthoferrite phase is more stable and it should thus be possible to fabricate films with single-crystal-like quality, at least in terms of the magnetic structure. In particular, large magnetic domains are desirable with few grain boundaries. However, when orthorhombic films are grown on common cubic substrates, such as SrTiO3, the film would spontaneously form various twinned structures due to the unequal lengths of the pseudocubic in-plane axes of the film. We have successfully grown YFeO3 films with large magnetic domains and a well-defined in-plane orientation of the crystallographic axes by using an orthorhombic NdGaO3 substrate. The (110) surface of a NdGaO3 crystal has a tetragonal in-plane unit cell, which can work as a growth template for a fully-strained epitaxial film, ensuring that the orthorhombic c-axis is in the plane of the film and that there are no 90° in-plane twin boundaries. To achieve such growth, the substrate has to have an atomically flat surface. The substrates were therefore annealed in air at 1000°C to obtain a step-and-terrace NdGaO3(110) surface. The YFeO3 films grown by pulsed laser deposition also exhibited a clean long-range step-and-terrace morphology (Fig. 1a), indicating that the films did not have 90° twin grain boundaries. The structural quality was confirmed through x-ray reciprocal space mapping (Fig. 1b), which showed that the films did not have a multi-domain structure. The magnetic ordering temperature of the films was verified to be close to 640 K by measuring the small residual ferromagnetic component of the canted spin structure. Hysteresis loops associated with the switching of the spontaneous residual magnetic moment were only observed when the magnetic field was applied in the plane of the film along the YFeO3 c-axis. The magnetic domain size was analyzed by magneto-optic Kerr rotation (MOKE) imaging. By slowly increasing the magnitude of the applied field, a gradual domain formation and domain wall movement could be observed in a narrow field range of 342 to 360 Oe (Fig. 2). The MOKE imaging showed that the magnetic domain size was on the scale of 100 µm or more. The magnon decay length in single crystals has been shown to be on the order of 0.5 µm, which means that for the purpose of device design, the films can be considered to have a single-domain structure. The well-ordered flat surface of the films provides a good starting point for constructing devices with very well defined interfaces. The YFeO3 films can be easily combined with various oxide ferromagnets, such as (La,Sr)MnO3 or metal layers.

References

- [1] C. Wang, M. Lippmaa, and S. Nakatsuji, J. Appl. Phys. 135, 113901 (2024).