New Intermetallic Compounds in Sm-Fe System Alloys

PI of Joint-use project: T. Saito

Host lab: Electron Microscope Section

Host lab: Electron Microscope Section

High-performance neodymium-iron-boron (Nd-Fe-B) magnets are applied to various advanced electromagnetic devices, including hard disk drives, electric vehicles, and medical equipment [1]. In particular, the production of electric cars equipped with Nd-Fe-B magnet motors has significantly increased, reflecting that regulations on internal combustion engines emitting large quantities of greenhouse gases have been proposed or enacted in many countries. The continuously growing demand for high-performance Nd-Fe-B magnets has raised severe concerns over their price and availability [2]. Under such circumstances, the development of permanent magnets using the relatively abundant rare-earth element Sm has become a focus of attention. Therefore, we have continued searching for new Sm-based rare-earth intermetallic compounds.

This study chose Sm-Fe system alloys as new Sm-based rare-earth intermetallic compounds. Although only three intermetallic compounds, Sm2Fe17, SmFe3, and SmFe2 phases are found in the Sm-Fe phase diagram [3], the formation of new intermetallic compounds, such as SmFe12, SmFe5, and Sm5Fe17 phases, has been reported in thin film processing [4-6]. It is necessary to obtain these materials in bulk form to evaluate the magnetic properties of these phases. This study investigates the possibility of producing these new intermetallic compounds through rapid solidification processing using a melt-spinning technique. The structures and magnetic properties of the melt-spun ribbons were investigated.

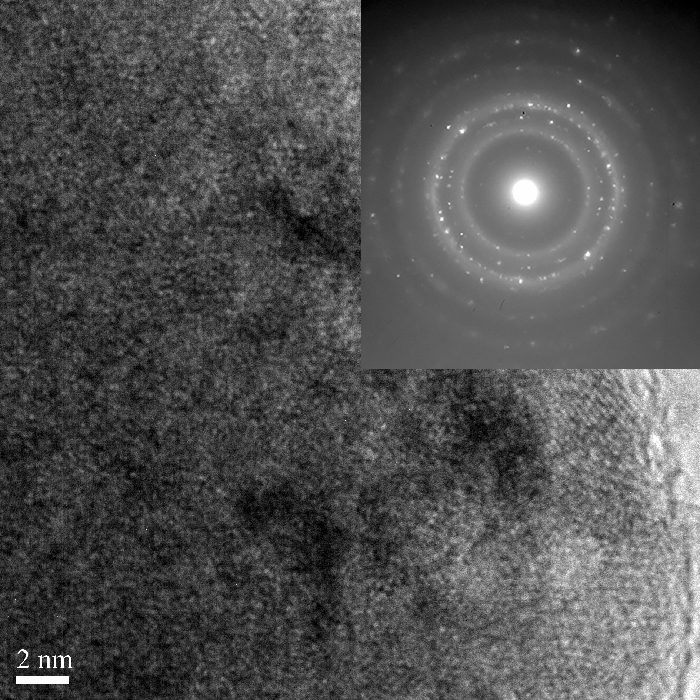

Since the new intermetallic compounds are metastable, it is impossible to produce alloys with these phases using the conventional casting method. Thus, the specimens were prepared by rapid solidification processing using melt-spinning. Figure 1 shows the transmission electron microscope (TEM) micrograph of the as-quenched SmFe5 melt-spun ribbon and the corresponding selected electron diffraction pattern. The electron diffraction pattern indicates that the fine grains in the TEM micrograph were in the SmFe5 phase. This confirms that the as-quenched SmFe5 melt-spun ribbon consisted of SmFe5 fine grains. Heat treatment of the as-quenched melt-spun ribbon resulted in crystal growth of the SmFe5 grains [7]. On the other hand, the SmFe12 and Sm5Fe17 phases were not obtained by rapid solidification processing using melt-spinning. These as-quenched melt-spun ribbons were amorphous. Although the Sm5Fe17 phase was produced by melt-spinning followed by optimal heat treatment, the SmFe12 phase was not obtained by annealing the SmFe12 melt-spun ribbon. The SmFe12 phase was found to be obtained by adding small elements, such as Ti or V, to the SmFe12 phase.

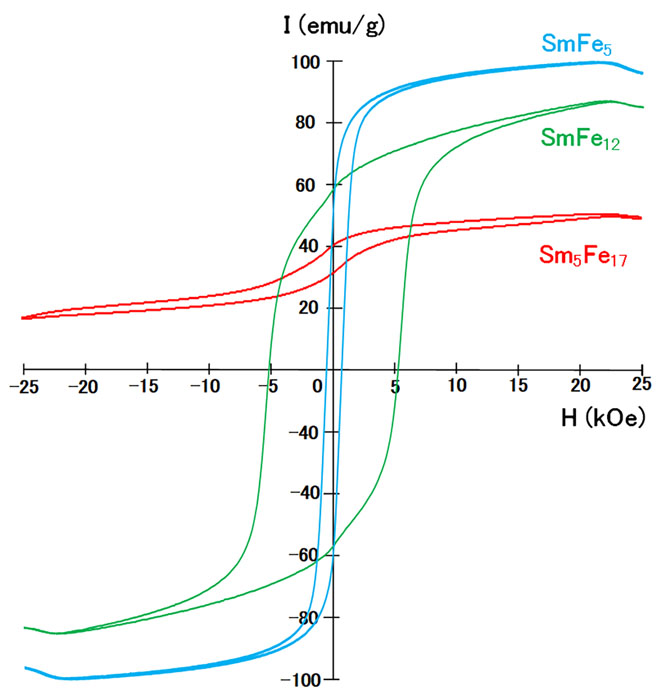

The magnetic properties of the new intermetallic compounds were evaluated by the vibrating sample magnetometer (VSM). Figure 2 shows the typical magnetic hysteresis loops of these phases. These new intermetallic compounds exhibited hysteresis loops as magnetic materials. The SmFe5 melt-spun ribbon showed a narrow hysteresis loop with moderate coercivity, and the SmFe12 melt-spun ribbon showed a wide hysteresis loop with high coercivity. On the other hand, the Sm5Fe17 melt-spun ribbon exhibited a minor loop, not a hysteresis loop. The coercivity of the Sm5Fe17 melt-spun ribbon was extremely high, over the applied field of 25 kOe in the VSM measurement, and only the minor loop was obtained in the Sm5Fe17 melt-spun ribbon.

This study obtained the new intermetallic compounds of the SmFe12, SmFe5, and Sm5Fe17 phases. However, the magnetic properties of these compounds are not yet comparable to those of high-performance Nd-Fe-B magnets. Further optimization of the annealing conditions and compositional modifications may improve the magnetization of these new intermetallic compounds.

References

- [1] G. Bailey, N. Mancheri, and K. V. Acker, J. Sustain. Metall. 3, 611 (2017).

- [2] T. Dutta, K. H. Kim, M. Uchimiya, E. E. Kwon, B. H. Jeon, A. Deep, and S. T. Yun, Environ. Res. 150, 182 (2016).

- [3] K. H. J. Busschow, J. Less-Common Met. 25, 131 (1971).

- [4] F. J. Cadieu, H. Hegde, R. Rani, A. Navarathna, and K. Chen, Mater. Lett. 11, 284 (1991).

- [5] P. Tozmana, H. Sepehri-Amina, and K. Hono, Scripta Mater. 194, 113686 (2021).

- [6] O. Yabuhara, M. Ohtake, Y. Nukaga, F. Kirino, and M. Futamoto, J. Phys.: Conf. Ser. 200, 082026 (2010).

- [7] T. Saito and D. Nishio-Hamane, AIP Advances 10,015311 (2020).