Y2O3 Phosphor Thin Films

PI of Joint-use project:R. Takahashi

Host lab: Lippmaa Group

Host lab: Lippmaa Group

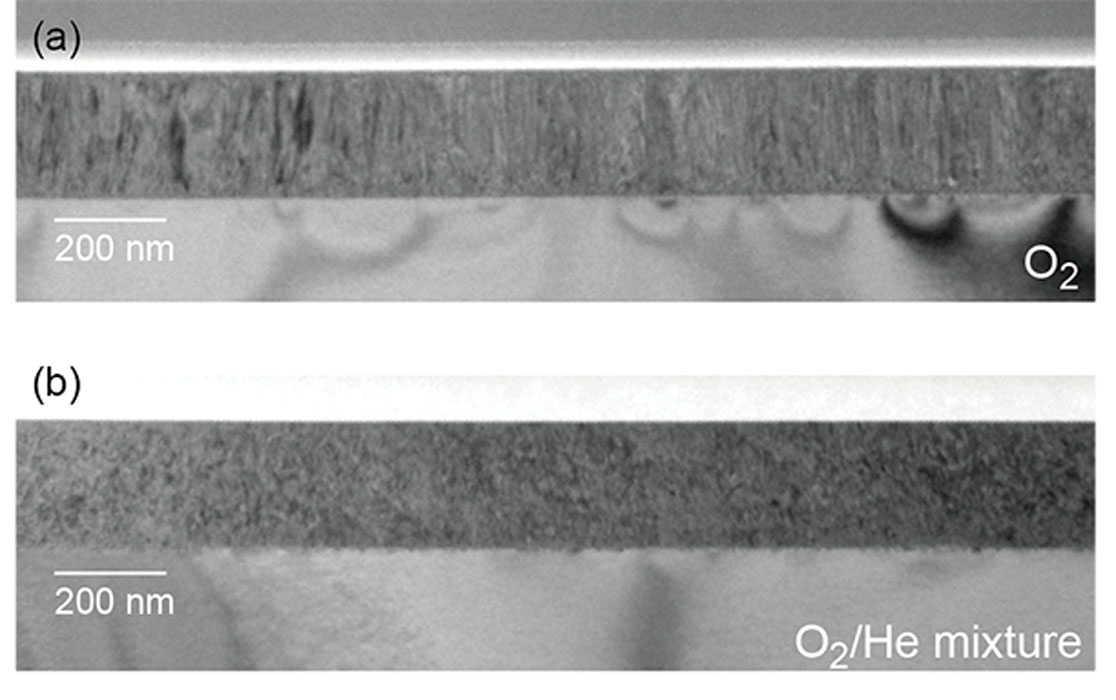

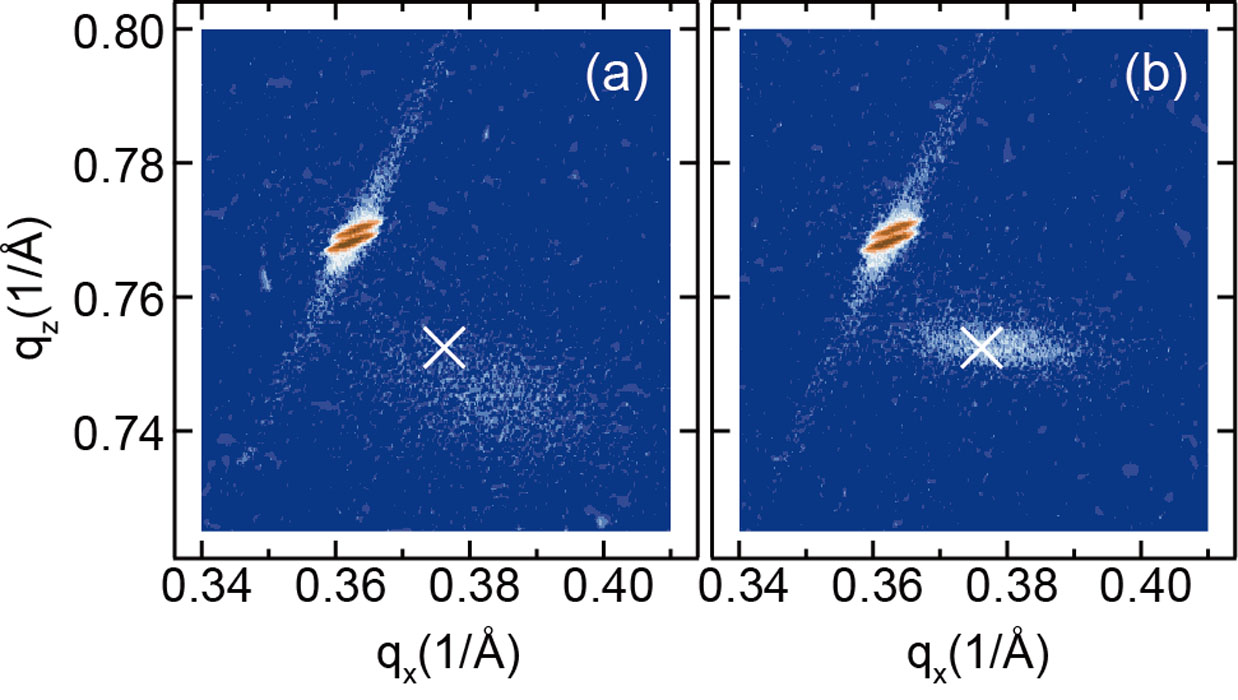

When thin film materials are grown by physical vapor deposition methods, such as sputtering or pulsed laser deposition (PLD), the kinetic energy of the adatoms arriving on the film surface has a significant effect on the crystallinity and defect density of thin films. In the PLD process, the incident adatom kinetic energy can reach 100 eV or more. The kinetic energy is increased at higher ablation laser energy density (laser pulse energy) due to a larger energy transfer from the laser beam to the ablated plasma. The kinetic energy is also dependent on the temporal ablation laser pulse shape. For typical excimer gas lasers, the pulse length is 20 ns, while solid-state garnet (YAG) lasers generate around 4 ns pulses, which means that the pulse rise time is faster for YAG lasers, leading to higher plasma kinetic energies. One of the advantages of PLD is the ability to use a very broad background gas pressure range, from a typical base pressure of 10-8 Torr to about 1 Torr. Increasing the process pressure of a background gas, such as oxygen, above 1 mTorr will increase the number of gas-phase collisions between ions in the ablation plume and the ambient gas, reducing the kinetic energy of the plume. However, high-pressure ablation also strongly reduces the growth rate, as many atoms colliding with the ambient gas are deflected from the plume and do not reach the film surface. We have developed an energy-moderated PLD technique using He as a buffer gas in the PLD chamber to reduce the kinetic energy of the plume. Due to the small mass of He, the gas-phase collisions reduce the plasma energy but do not deflect the atoms away from the plume, allowing films to be grown at the desired growth rate, but at a lower incident kinetic energy of deposited atoms, reducing the density of point defects in the film. The point defect density is a particularly serious problem for optical materials, such as phosphors, where defects reduce the intensity and the lifetime of the luminescence signal. We have explored the effect of plume energy moderation on the properties of PLD-grown Y2O3 phosphors. The effect of the energy moderation can be seen in the x-ray reciprocal space maps of two films (Fig. 1), both grown at an oxygen partial pressure of 10-4 Torr. A film grown in a conventional process (Fig. 1a) shows diffuse film scattering that is systematically shifted from the expected lattice parameter (marked with a white cross). When the PLD chamber is additionally filled to 100 mTorr with He, the film peak becomes much narrower and shifts to the expected bulk lattice parameter position, indicating that the crystalline defect density was dramatically reduced by the plume energy reduction. The microstructure change is clearly visible in cross-sectional transmission electron microscope images of films grown in a low-pressure oxygen environment and in the presence of He gas at a pressure of 100 mTorr (Fig. 2). When a Y2O3 film was grown under conventional conditions, without the He moderator, the film formed columnar grains that extend through the thickness of the film. Such grain boundaries can effectively quench the light output of a phosphor material. This columnar structure was completely eliminated when a film was grown in a He/O2 gas mixture at a total pressure of 100 mTorr. Time-of-flight measurements indicated that the kinetic energy of the plume was reduced by a factor of about 7 at 100 mTorr of He. The reduction of the defect density of the films significantly increased the photoluminescence intensity of the Eu-doped yttria phosphor films.

Fig. 1. X-ray reciprocal space maps of Y2O3 films grown on SrTiO3 at an oxygen pressure of 10-4 Torr (a) and in a mixture of 10-4 Torr O2 and 100 mTorr He. The addition of the He buffer increased the film peak intensity, reduced the peak width, and shifted the film peak close to the expected bulk lattice parameter (marked with a white cross).

References

- [1] S. Suzuki, T. Dazai, T. Tokunaga, T Yamamoto, R. Katoh, M. Lippmaa, and R. Takahashi, J. Appl. Phys. 135, 195302 (2024).