Dynamics Fracture Behaviors of Slide-Ring Gels

Mayumi Group

Tough hydrogels have been attracting a lot of interest because of their potential application for biomaterials. To improve the mechanical strength of hydrogels, various chemical design of polymer networks have been proposed in the last two decades. One of the promising strategies to toughen gels is to introduce weak “sacrificial” crosslinks into polymer networks [1]. The sacrificial bonds in tough polymer gels are broken under deformation, and a part of input mechanical energy is dissipated, which leads to the large fracture energy of the dissipative gels. A problem of the dissipative tough polymer gels is their low mechanical recoverability. When reversible bonds (e.g. hydrogen bonds, ionic bonds, etc.) are utilized as sacrificial bonds, the broken sacrificial bonds can be recovered, but it takes a relatively long time (at least minutes) for complete recovery. For the applications as implant biomaterials such as artificial ligaments and prosthetic joints, the mechanical instant recoverability is needed because they should show constant mechanical responses under repeated deformations at a high frequency (e.g. 1 Hz).

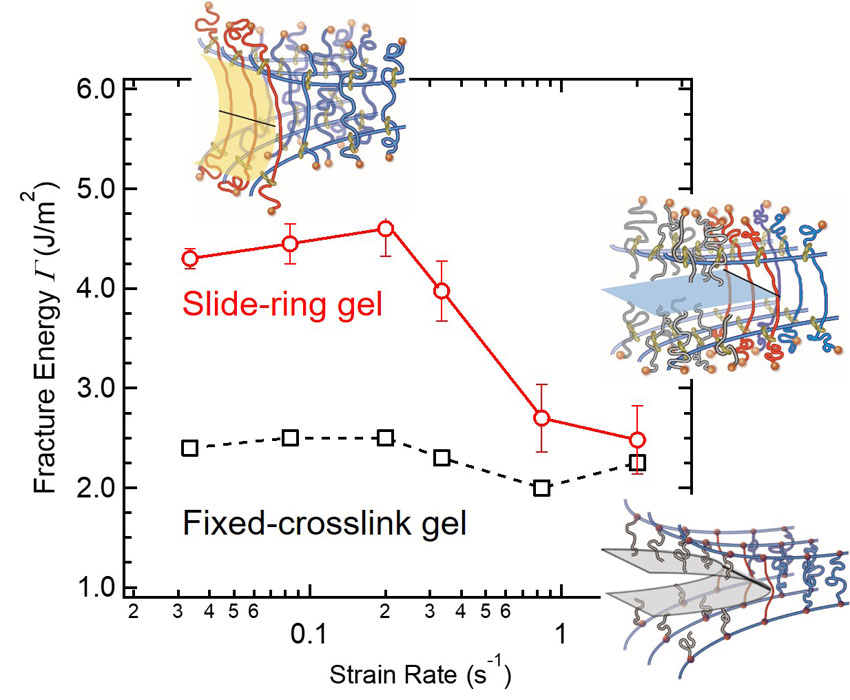

Another tough polymer gel is slide-ring (SR) gel, in which polymer chains are cross-linked by ring molecules (Fig.1) [2]. The sliding of the movable cross-links composed of rings homogenizes network structure and reduces stress concentration in polymer networks, which results in high deformability and softness of SR gels. We have been investigating toughening mechanism of SR gels composed of polyethylene glycol (PEG) and cyclodextrin (CD). For conventional polymer gels cross-linked by fixed covalent bonds, the fracture energy is dominated by the strand length between cross-links. In the case of SR gels, the sliding of the cross-links enlarges the strand length and enhances the fracture toughness [3].

A unique feature of SR gels is their high mechanical recoverability. SR gels show no mechanical hysteresis under repeated stretching. This suggests that the sliding movement of the cross-links is faster than breaking/reforming dynamics of the reversible sacrificial cross-links. We systematically investigated the crack propagation behavior of SR gels at various strain rates to evaluate the sliding dynamics of the movable cross-links [4]. At a certain strain rate and crack propagation velocity, a drastic decrease of the fracture energy was observed (Fig.1). For lower strain rates and crack propagation velocities, the slide-ring cross-links have enough time to slide along the polymer axes, which leads to the enhanced fracture energy. At fast fracture, however, the sliding of cross-links cannot catch up with the network deformation, and the fracture energy decreases to the same level as that of a fixed cross-link gel. From the critical crack propagation velocity at the transition point, we estimated the time scale of the sliding dynamics to be micro-seconds. This result is consistent with the diffusion coefficient of the sliding dynamics for CDs on PEG axis evaluated by a full atomistic molecular dynamics simulation [5]. The fast sliding motion of the cross-links is the origin of the high mechanical recoverability of SR gels under repeated deformations. SR gels exhibits high toughness and mechanical recoverability, which are needed for implant biomaterials and elastomer actuators for soft robots.

References

- [1] J. Y. Sun, X. Zhao, W. K. Illeperuma, O. Chaudhuri, K. H. Oh, D. J. Mooney, J. J. Vlassak, and Z. Suo, Nature 489, 133 (2012).

- [2] K. Ito, Polym. J. 39, 489 (2007).

- [3] C. Liu, H. Kadono, K. Mayumi, K. Kato, H. Yokoyama, and K. Ito, ACS Macro Lett. 6, 1409 (2017).

- [4] C. Liu, H. Yokoyama, K. Mayumi, and K. Ito, Mech. Mater. 156, 103784 (2021).

- [5] Y. Yasuda, Y. Hidaka, K. Mayumi, T. Yamada, K. Fujimoto, S. Okazaki, H. Yokoyama, and K. Ito, J. Am. Chem. Soc. 141, 9655 (2019).