Pulsed Laser Deposition with Rapid Target Switching

Y. Matsumoto and M. Lippmaa

Pulsed laser deposition (PLD) is one of the most common techniques for growing complex oxide thin films. The biggest merit of PLD is the near-stoichiometric transfer of material from a polycrystalline ceramic target to a single-crystalline thin film, which means that it is usually not necessary to tune individual cation ratios during the crystal growth process. Indeed, PLD became the method of choice for developing high-temperature superconductor thin films and devices due to the simplicity of phase and stoichiometry control.

The PLD process is based on the use of a high-intensity pulsed laser that momentarily heats the surface of a ceramic source material pellet, forming a rapidly expanding plasma cloud in vacuum or in a low-pressure reactive gas ambient. Due to the pulsed nature of the process, the surface of a growing film reaches a high level of supersaturation when the plasma plume arrives, but this very high instantaneous deposition rate is followed by a long relaxation period of up to about a second. The dynamic aspect of the crystal growth is therefore also important in determining the growth mode and crystallinity of a film.

In recent years, there is increasing interest in materials property mapping and the use of combined computational and experimental materials data to feed machine learning models for aiding materials discovery and optimization. In thin film property mapping experiments, it is necessary to grow large numbers of thin film samples with slightly different compositions. In a traditional PLD process, this would require the synthesis of a large number of bulk compositions for use as PLD ablation targets, which is technically difficult. Multi-target PLD has been used to avoid this problem by using just two ablation targets to grow mixed-composition phases. For example, by alternating ablation from SrTiO3 and BaTiO3 targets, it is possible to grow any intermediate composition in the Ba1-xSrxTiO3 phase space. Since each unit cell layer usually requires up to a hundred ablation pulses to grow, it is easy to adjust compositions on a percent scale. However, switching between two targets generally requires mechanical motion of the target stage, which is a slower process than the normal ablation pulse period. Since adatom surface migration during the interpulse period affects the film microstructure, the longer time delay of target exchange may lead to a nanoscale multiphase film of, e.g., SrTiO3 and BaTiO3 domains instead of a mixed Ba1-xSrxTiO3 crystal.

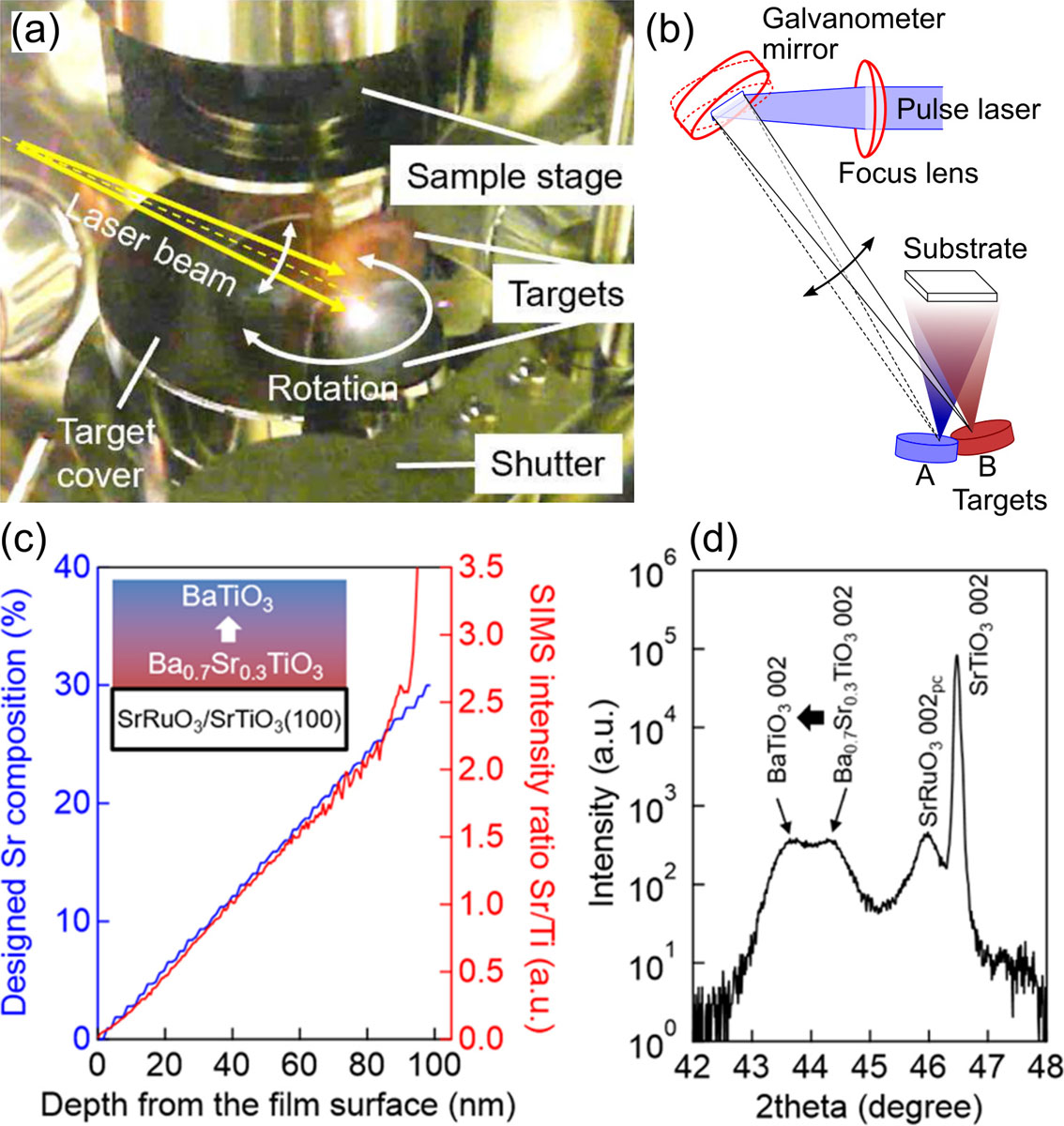

In this project, supported by the Joint Use program, a rapid beam deflection system was developed to switch ablation between two target materials on a millisecond scale.[1] The experimental setup is illustrated in Figs. 1(a,b). A galvanometer mirror is used to direct ablation laser pulses on one of two targets without having to move the target stage. The mirror motion is fast enough to interleave depositions from two targets in a 1:1 pulse sequence at laser pulse rates of up to 200 Hz.

Fig. 1. (a) Photograph of the ablation target stage, showing the ablation spot on the lower target. (b) Schematic diagram of the rapid galvanometer beam switching between two targets. (c) Design (blue) and measured (red) composition of a (Ba,Sr)TiO3 film. The x-ray diffraction pattern in (d) shows that the film lattice parameter varied continuously in the film.

Various film synthesis experiments were used to test the benefits of rapid sequential deposition of various mixed-composition oxide films. The experiments clearly showed the benefit of rapid target switching in synthesizing (Ba,Sr)TiO3, (Bi,Sm)FeO3, (Mg,Zn)O, Ni-Ge, and Ni-Si films. A particularly interesting capability of this new rapid target switching PLD system is depth direction grading of film composition for tuning the lattice parameter, doping level, crystal symmetry, or other properties without sacrificing the deposition rate or risking phase segregation when slower mechanical target stage motion is used for multi-target deposition.

An example of a depth-graded Ba1-xSrxTiO3 film composition is shown in Fig. 1(c). The Ba content was adjusted over the 100 nm thickness of the film from 0 to 30% as shown by the design plot (blue) and verified by Secondary Ion Mass Spectrometry (SIMS) as shown in red. The continuous change of the lattice parameter can be seen in the x-ray diffraction pattern for a gradient film grown on a SrRuO3 electrode layer on a SrTiO3 substrate. The spread of the (Ba,Sr)TiO3 film peak corresponds to the continuous composition gradient in the film. This type of gradient films can be used in novel types of photoelectrochemical electrodes and for constructing polar films with an internal electric field gradient related to the depth-variable polarization of the lattice.

References

- [1] S. Maruyama, N. Sannodo, R. Harada, Y. Anada, R. Takahashi, M. Lippmaa, and Y. Matsumoto, Rev. Sci. Instrum. 90, 093901 (2019).