Large Magnetic Anisotropy of L10 Ultrathin Film Grown by Nitrogen-surfactant Epitaxy

Komori Group

For the development of useful magnetic materials, important are uniaxial magnetic anisotropy with high magnetic moment, coercivity, and transition temperature. Moreover, for their wide use, rare-element free materials are strongly required. One of the excellent candidates of such magnetic materials is L10 FeNi with large uniaxial anisotropy energy, Ku, up to 1.3 MJm-3. While its single crystal cannot be prepared by conventional macroscopic crystal growth, the single-crystal films have been fabricated by layer-by-layer epitaxial growth on Cu(001) and other substrates in a vacuum. The Ku values of the films are, however, lower than the above ideal one. Thus, the magnetic anisotropy perpendicular to the film has not been realized because the in-plane film shape anisotropy is larger than the magnetocrystalline anisotropy. The limitation in the epitaxial films has been attributed to the imperfect atomic layer-by-layer mode in the alternative deposition process of Fe and Ni atoms and the intermixing of the two elements at the interface.

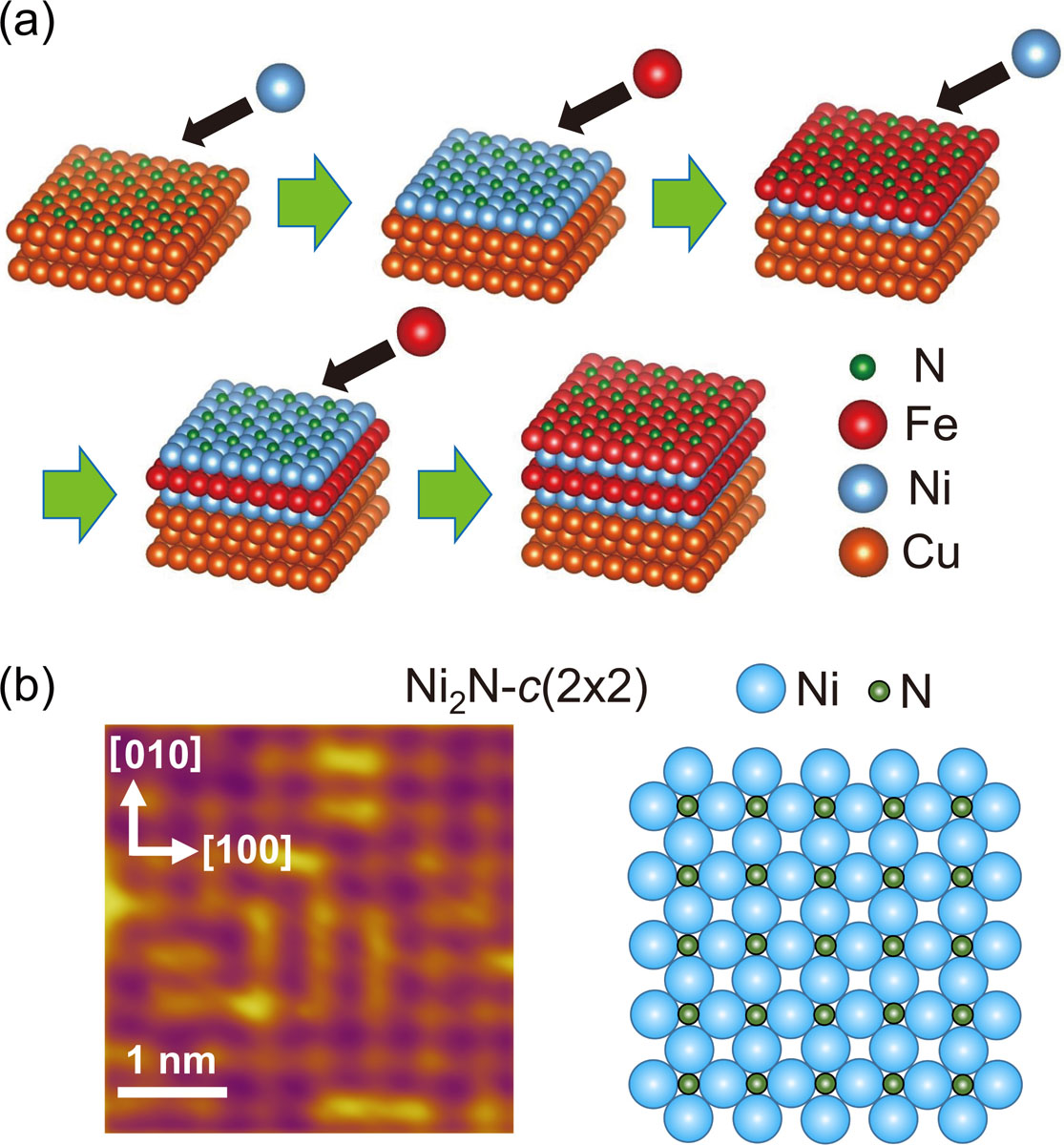

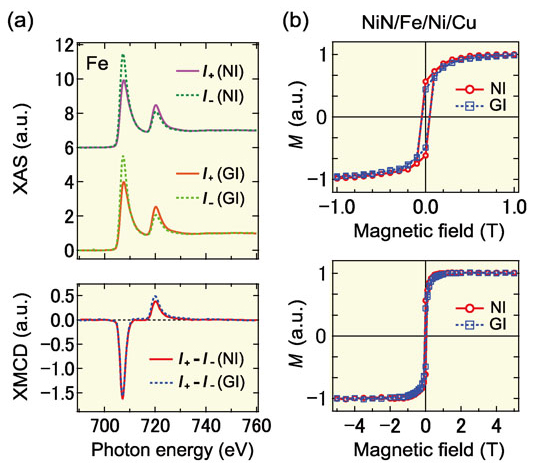

We have demonstrated significant improvement of the uniaxial magnetic anisotropy of an L10 FeNi epitaxial film prepared by surfactant epitaxy of Fe and Ni atomic layers using nitrogen (N) atoms and the deposition on a cooled Cu(001) substrate [1]. The N-surfactant epitaxy, that is, successive and selected segregation of the N atoms to the surface during the alternate Fe and Ni monolayer (ML) deposition in the present case, suppresses the mixing between Fe and Ni atoms during the deposition and annealing. The schema is given in Fig. 1(a). It was previously shown on the N-adsorbed Cu(001) substrate that N atoms segregate to the surface during the Fe and Co deposition without mixing between the deposited metal and the substrate Cu atoms [2]. This is quite in contrast to the mixing during the deposition of magnetic transition metals on the same substrate [3]. Sharp interface between the atomic layers of Fe and Ni in the film is ensured by the present method. A monatomic layer is grown on the cooled substrate while bilayer islands are formed at room temperature. Satisfactory growth of the L10 FeNi films up to four monolayers was confirmed after post-annealing process at 430 K by in-situ X-ray photoelectron spectroscopy, scanning tunneling microscopy and low energy electron diffraction. Magnetic properties were studied using element-specific soft-X-ray magnetic circular dichroism (XMCD). The value of Fe L2,3 XMCD is an order of magnitude larger than that of Ni L2,3 XMCD, and thus the Fe monolayer dominates the magnetism of the film. The results of the NiN/Fe/Ni trilayer are shown in Fig. 2. The Fe hysteresis curve measured at 8 K indicates the out-of-plane magnetocrystalline anisotropy is large enough for overcoming the in-plane film shape anisotropy. According to the XMCD sum rule analyses, both Fe and Ni magnetic moments increase with increasing the thickness of the FeNi film.

Fig. 1. (a) Schematic model of an FeN/Ni/Fe/Ni film formation process on Cu(001) by surfactant epitaxy using N atoms. First, monolayer c(2x2) Ni2N is formed on Cu(001) surface as shown in (b) by N adsorption and Ni deposition. Then, 1-ML Fe is deposited below 150 K. After annealing above 300 K, N atoms segregate to the Fe surface and Fe2N monolayer is formed. Next, on top of this surface, 1-ML Ni is deposited below 150 K. By repeating deposition and annealing, the L10 FeNi film is prepared. (b) STM image of a Ni2N atomic layer on Cu(001) (left) and its ball model (right). The 0.5-ML N form c(2x2) structure with 1x1 Ni atoms [1].

Fig. 2. (a) Fe L-edge XAS (upper) and XMCD (lower) spectra of the NiN/Fe/Ni trilayer for the NI and GI geometries. In the NI (GI) geometry, the magnetic field direction is 0° (55°) off from the surface normal to the [100] direction of the Cu(001) substrate. The XAS intensity was measured with the photon helicity parallel (I+) and antiparallel (I−) to the external magnetic field of 5 T at 8 K. (b) Narrow- (upper) and wide- (lower) range Fe magnetization (M) curves of the NiN/Fe/Ni trilayer [1].

References

- [1] K. Kawaguchi et al., Phys. Rev. Material 4, 054403 (2020).

- [2] D. Sekiba et al., Surf. Sci. 590, 138 (2005).

- [3] H. L. Meyerheim et al., Phys. Rev. B 71, 035409 (2005).