Enhanced Piezoelectric Properties of Al-substituted Langasite Family Crystals

H. Takeda, T. Hoshina, and T. Tsurumi

La3Ga5SiO14 (langasite; LGS) family single crystals are the most attractive piezoelectric materials for use at high temperature, because the crystals show no phase transitions up to its melting temperature. Recently, combustion pressure sensors made of the LGS and La3Ta0.5Ga5.5O14 (LTG) substrates have been developed on a laboratory scale. A low temperature dependence of the piezoelectric properties and a high electric resisitvity at high temperature are still necessary to improve in the langasite family crystals for the practical use. From these reasons, we have developed aluminum substituted LGS, La3Nb0.5Ga5.5O14 (LNG) and LTG crystals.

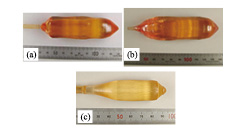

Fig. 1. Aluminium substituted langasite family crystals grown by Czochralski technique. (a) La3Ga4.1Al0.9SiO14 (LGAS0.9), (b) La3Nb0.5Ga5.3Al0.2O14 (LNGA0.2), and (c) La3Ta0.5Ga5Al0.5O14(LTGA0.5).

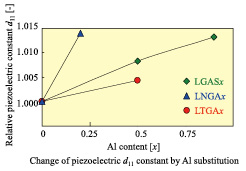

Fig. 2. Variation of piezoelectric strain d11 constants as a function of Al-content for aluminium substituted langasite family crystals.

Figure 1 shows the crystals with three Al-contained compositions, La3Ga4.1Al0.9SiO14 (LGAS0.9), La3Nb0.5Ga5.3Al0.2O14 (LNGA0.2), and La3Ta0.5Ga5Al0.5O14(LTGA0.5), which were grown by Czochralski technique. All the crystals showed a smooth surface, and were transparent with an orange color. No cracks and inclusions were found inside the grown crystals. Although segregation phenomena should occur during crystal growth due to solid solution crystals, all the crystals showed very small variation in the Al2O3 concentration. This means that the chemical compositions of LGAS0.9, LNGA0.2 and LTGA0.5 are very close to congruent melting composition.

Langasite family crystals belong to space group P321. There are four kinds of cation sites in the structure. They are composed of a decahedral site and an octahedral one, two kinds of tetrahedral ones. Structure analysis revealed that Al atoms are distributed on octahedral and two tetrahedral sites except for the decahedral site, which is occupied by La. Isotropic decrement of lattice constants and no systematic change of structural distortion were observed in all the crystal. The decrement of lattice constants proved that Al3+ was substituted for Ga3+, because Al has small ionic size and low atomic weight compared with gallium.

Figure 2 shows the changes in the piezoelectric constant d11 as a function of x in Al-substituted crystal. With an increase in the Al content, the absolute piezoelectric strain modulus d11 increases by about 1.3%, 1.5% and 0.6% for LGAS0.9, LNGA0.2 and LTGA0.5, respectively. This is because elastic compliance constant sijE increased with Al content. With increasing Al content, s11E increased 0.3 to 2.4%. This increment implies that the crystal becomes hard elastically. This should result from shrinkage of the crystal lattice, that is, a decrease of lattice constants a and c, by Al substitution for Ga.

The temperature dependence of the piezoelectric constant d11 and electric resistivity ρ were investigated from room temperature to 700oC. Very small influence of Al substitution on temperature dependence in all crystals is observed. The Al substitution hardly affected the thermal behaviour of the piezoelectric properties of the langasite family crystals. The LTGA0.5 crystal shows the smallest variation (±1%) of all the crystals About the ρ values, the Al-substituted crystals have high ρ values of one order of magnitude, compared with pure crystals at high temperatures. The ρ value is almost satisfied for the required values at 400 oC. The Al substitution is effective way to improve the electric resistivity for the langasite family crystals. Especially, the LTGA0.5 crystal is the most promising candidate for combustion pressure sensor material

References

- [1] H. Takeda, J. Yamaura, T. Hoshina, and T. Tsurumi, J. Ceram. Soc. Jpn. 118, 706 (2010).

- [2] H. Takeda, J. Yamaura, T. Hoshina, and T. Tsurumi, IOP Conf. Ser.: Mater. Sci. Eng. 18, 092020 (2011).